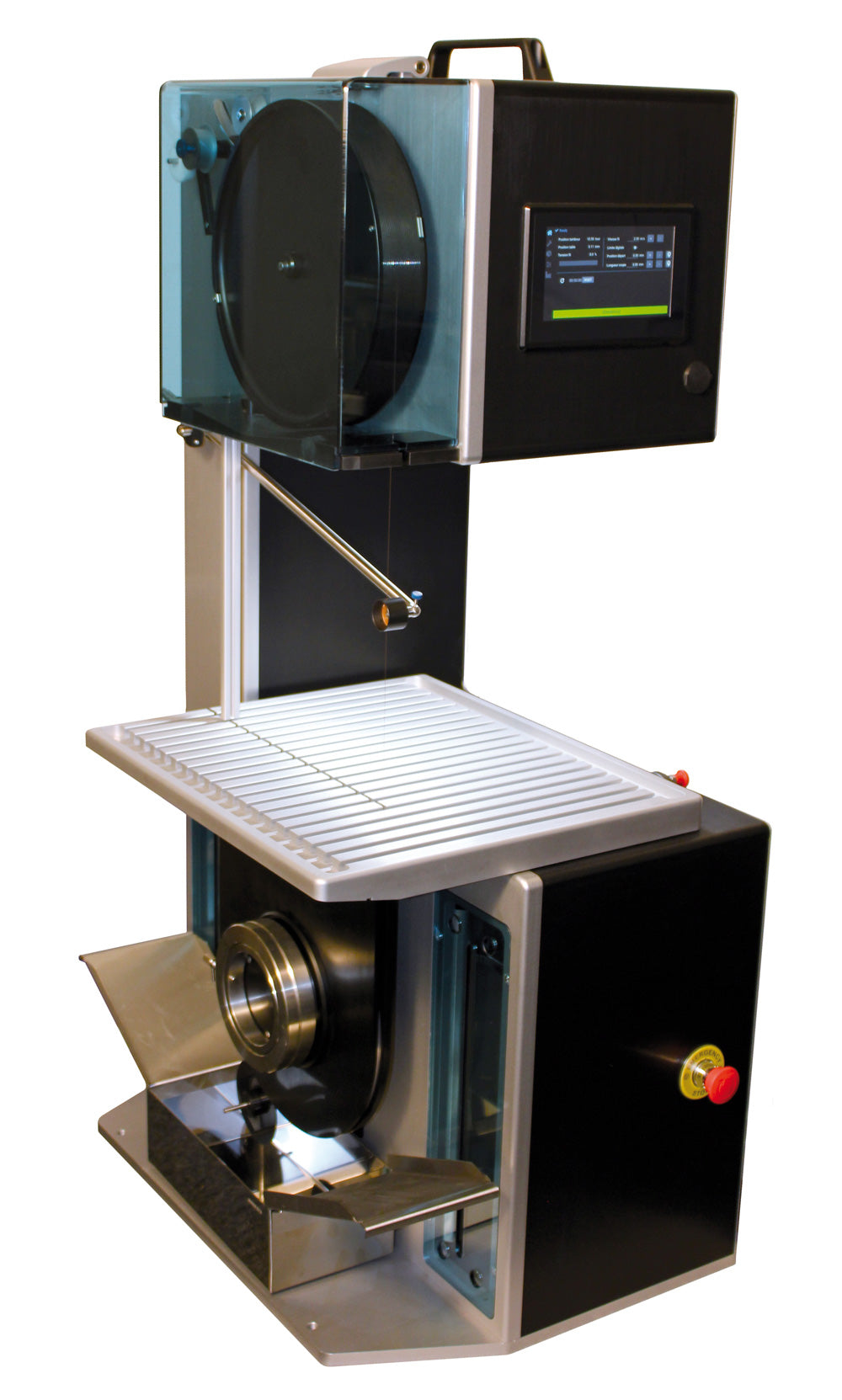

WELL® Diamond Wire Saw MODEL 6500

WELL® Diamond Wire Saw MODEL 6500

Model 6500 Premium (65.P.000)

Of all Well saws, the 6500 model is, without question, the most universal. Compact and easy to use, it can meet the needs of industrials as well as laboratories.

Very often, it avoids a lengthy and costly polishing job.

The proven and much sought-after Well cutting principle is integrated in the 6500 model, for cutting medium-sized samples (300 mm in height, 300 mm in width).

The length of the sample is virtually unlimited as long as support for the work piece can be provided. To cut small parts, the wire guide rollers can be lowered as close as possible

to the sample. In addition, optional micrometric tables are supplied when cutting accurate slices is needed.

Since the patented diamond embedded wire, of approximately 15 metres in length, travels in both a forward and reversing direction, the sample must be firmly secured to the worktable. The tension on the wire on the “T-slotted” table can be adjusted with the

tensioning mechanisms supplied with the saw.

An electronic protection device is installed at the heart of the machine for a longer lasting wire. If the cutting pressure on the wire is too high, a warning will be displayed on the screen. With this new technology, even very fine wires can be installed.

An electronic ruler is installed underneath the work table. It is used to display the cutting progress on screen. You can also simply modify the parameters in order to use it as a depth-of-cut stop allowing you to adjust the stop of the machine precisely.

With its sleek design, it is easy to maintain and use. With the semi-automatic wire winding system combined with the latest drum technology, replacing the wire is staggeringly simple.

Work table with motorised feed available upon request

THE CUTTING PRINCIPLE OF THE WELL PRECISION DIAMOND WIRE SAW MODEL 6500

The WELL 6500 model is a benchtop saw. This is probably the most versatile saw. Indeed, when creating this model, have been applied the operating principle of the WELL 3000 series diamond wire saws (see Model 3500 for details). Designed as a benchtop model, the WELL 6500 incorporates state-of-the-art technology and offers additional capabilities compared with the WELL 3000 series. It adapts to a wider range of materials and larger sample sizes.

All WELL diamond wire saws use a drum with precision threaded grooves machined into the surface to hold the diamond wire in place. The 30-metre-long diamond wire used by Model 6500 is attached and wound on the drum by a winding device, mounted on a lead screw of the same size as the drum and connected to a motor that rotates in both directions.

The constant force (feed speed) of the wire against the sample is obtained by counterweights. The feed speed is determined by the resistance of the material, which is thus not subjected to mechanical stress. The saw motor housing is guided by precision guides on ball bearings. In addition to the possibility of adjusting the force of the wire, its speed is also adjustable via a continuously variable potentiometer.

Model 6500 cuts samples with the wire travelling vertically. The sample can be positioned inside or outside the loop thereby allowing for accurate positioning prior to and viewing of the sample during the cutting process. The sample holder is attached to a horizontal mobile table. Tensioning of the wire is also accomplished through the use of weights.

It enables you to configure the following data:

- Wire tension (gram)

- Wire speed (metre / second)

- Feed power (gram)

The configuration of these parameters makes it possible to use different diamond wires, including the finest wires (diameters 0.13 to 0.50 mm). The 308 mm diameter drum with 30m of diamond wire offers a large working space with a cutting depth of 300 mm, and enables the adaptation of sample holders to the micrometer table supplied as an option with the machine.

It shares the same design as the Model 4500.

Cutting is performed by the movement of the table on the workpiece fixed on it or on a standard or special sample holder.

The saw is equipped with a high-quality colour touchscreen control. Different parameters can be configured. For the convenience of the operator and longer wire life, a constant display on the screen alerts the operator when wire tension is too high. This prevents wire breakage due to excessive feed power.

The depth of the cut can also be easily configured. When the wire reaches this setting, the saw will automatically stop.

Wire replacement is surprisingly easy and quick. All the steps of the process are displayed on the screen. It is an operation that can be carried out by anyone.

This model is built with aluminium plates and high-quality surface treatment. Virtually all the screws that fasten the plates together are invisible. These large, smooth surfaces make for easy cleaning and maintenance.

There is no restriction to the length of the pieces to be cut as long as they can be reasonably placed on the worktable. It is also possible to use the guide pulleys provided with the saw to precisely hold the wire in place.

The workpiece must be securely fastened to the work table because the patented 30 m long diamond wire constantly winds and unwinds. The tensioning mechanisms provided with the saw facilitate the tensioning of the wire on the T-slot table. The feed, which operates by gravity, is adjustable between 100 and 1500 g. This relatively low force results in a slightly longer cutting time than the average of the other cutting tools available. However, this process offers undeniable advantages.

It is up to the user to choose between a faster cut that is often more aggressive for materials and the slightly longer but more precise WELL process.

Ergonomic and safe

Although the wire can reach a speed of 2.5 m / s, accidental or intentional contact with the moving wire does not cause injury. It is possible to observe the cutting process at any time from a comfortable distance without being hampered by a cumbersome protective cover. Due to the relatively low forces in action during cutting, it is quite simple to attach the workpieces. If the wire breaks, the saw stops automatically.

Available in a floor (with adapted furniture) and benchtop version, the 6500 can accommodate larger workpieces up to 300 mm high and 300 mm deep and weighing up to 20 kg (approx. 44 lbs). Wire tension is possible up to 20 kg (about 44 lbs).

Various adaptable holding accessories are provided as standard or can be made on request.

THE ADVANTAGES OF THE WELL PRECISION DIAMOND WIRE SAW MODEL 6500

- The WELL 6500 saw for medium-sized workpieces

- Robust construction for sawing workpieces up to 20 kg

- Maximum depth and height of the cut: 300 mm.

- Diamond wire of Ø 0.13 mm 10 μ to 0.50 mm 64μ or Ø 0.35 mm 64 μ are available.

- Wire speed can be continuously adjusted from 0 to 2.5 m / s.

MODEL 6500 Base Features:

| Cutting Wire position: | Vertical |

| Protecting Wire System (PWS): | Standard |

| Automatic Winding System (AWS): | Standard |

| Cutting feed: | Gravity (+/- 20kg) |

| Machine control : | Touch Screen LCD 7’’ – 1024 x 600 Pixel |

| Drum diameter: | 308mm |

| Pulleys diameter: | 308mm |

| Table surface: | 400mm x 370 mm |

| USB Output: | Yes |

| Wire diameter: | 0.13-0.50mm |

| Wire length: | 30m |

| Wire speed: | 0 - 2.5m/s |

| Wire tension: | 1 - 20kg |

| Cleaning of wire: | Cutting liquid |

| Sample weight: | <15kg |

| Sample dimension: | <300 x 300 x 300 mm – Ø 300 mm |

| Power supply: | 230 V-110 V / 50-60 Hz |

| Electric motor power: | 240W |

| Weight without accessories: | 105kg |

| Dimensions: | 650mm(L) x 480mm(W) x 1200mm(H) |

The Model 6500 is delivered ready to use and includes:

- Original WELL Diamond Wire: 0,35mm diameter, 64 µ grit, 120m length

- Cutting liquid concentrate:500ml

Various accessories are available for WELL Model 6500 diamond wire saws. Click here for details.

Documentation

Documentation