Quality Control Test Standard-A

Quality Control Test Standard-A

WHEN NOT IN USE, THE STANDARD SHOULD BE STORED UNDER VACUUM OR IN A SUITABLE DESICCATOR IN A TEMPURATURE CONTROLLED ENVIRONMENT

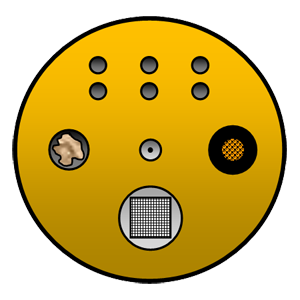

This Standard block Contains:

- 6 Individual Standards (customer's choice)

-

150 μm Faraday cup used for Beam current stability

150 μm Faraday cup used for Beam current stability

- Hole 1 - BSE Duplex Brass used for Backscattered Detector (BSE) resolution

- Hole 2 - Silicon Test Grid used for Magnification calibration & image distortion

- Hole 3 - Au/C BSE specimen used for SEM BSE resolution, 5 – 150nm particles

Selectable Materials for the QCTA and QCTB Standards

High Purity Materials Recommended for Energy Calibration

| Si | Sc | Ti | V | Cr | Mn |

| Fe | Co | Ni | Cu | Zn |

X-ray peaks often involve multiple lines therefore in order to achieve accurate

calibration, a large peak with well-known line energies and intensities is required.

We recommend that for energy calibration a pure element is used; Si, Co, Ni or Cu are the most common.

High Purity Materials Recommended for Beam Measurement

| C | Si | Ti | V | Cr | Mn |

| Fe | Co | Ni | Cu | Zn |

Pure Co resists oxidation and polishes well and is therefore the most suitable choice to monitor beam current when you want to obtain accurate un-normalized or "absolute"

estimates of composition. However, below 15kV, Co K-line is weakly excited and it is preferable to choose another pure element for monitoring.

If the beam measurement material is oxidized, contaminated or has a rough surface, then this will have a direct effect on the analysis results. When using very low

accelerating voltages, a pure carbon standard (ideally glassy carbon) can be used for beam calibration. The resolution must be sufficient to leave background regions either side of the carbon peak, so that the peak is clearly separated from the triggered noise peak (near zero keV) and any oxygen peak near 0.5 keV. Furthermore, the voltage must be sufficient to excite an adequately large C K-line emission.

Most EDX software allows calibration using the zero strobe peak and a known element.

If the software on your system does not allow this then calibration is recommended using an Al+Cu sample. These two 1mm wires are embedded side by side in a single hole. For low accelerating voltages a Al/C sample would be used.

Selectable Materials for the QCT Standards

Recommended Materials for Checking Energy Resolution

| Mn | Cu | C | F |

Resolution is quoted as the width of the peak at half its maximum height (FWHM). The lower the number the better the resolution of the detector and therefore the better it will be at resolving peaks due to closely spaced X-ray lines.

Many manufacturers test the performance of an EDS detector using Fe55. This is con-venient as it can be achieved without the need of mounting the detector on an SEM.

The resolution of a detector is traditionally specified for the Manganese Kα X-rays at 5.895 KeV as this is the energy of the most intense X-ray line emitted by the Fe55 source.

Mn Kα energy is most commonly used to specify EDS resolution as the peaks are well separated. However, much more serious overlaps occur below 3keV and the resolution performance at low energies is critical to good performance for all elements. Mn (FWHM) is a very insensitive measure to characterize the noise of a detector and pre-dict the resolution at low energy. Therefore, to characterize the resolution of a detector at low energy, the resolution is also quoted for another line, typically Fluorine Kα.

The resolution of the C Kα peak measured using pure Carbon is very useful due to its sensitivity to noise and incomplete charge collection. A low value guaranteed here means excellent detector resolution for all energies.

Recommended Material for Checking Detector Performance Changes

| Ni | Cr |

A gradual decrease in low energy sensitivity over time will result in a decrease in the height of peaks at low energy. This can be checked by monitoring the relative height of K and L lines from a transition metal element. The ratio of L to K line heights from pure nickel measured at 20kV is a common test. A more sensitive test for the presence of ice and water vapour on a detector window is to look at the L spectrum from pure Cr.

Miscellaneous Materials

Be is often used for checking the low-end sensitivity of high-performance detectors.

BN is used for checking the low-end energy performance of thin window and window-less detectors.

SiO2 is used to test the Oxygen sensitivity of the EDS.

Almandine is used to verify the quant. analysis achieved for oxides after calibration.

AISI 316 S/S is used to verify the quant. analysis achieved after calibration.

See also SEM Magnification and Resolution Specimen Options

Supplied in a specially designed storage/transportation case that contains:

• The standard—protected by an additional specially designed case

• A full electronic booklet on a USB, containing:

• The standard plan/layout

• Certificates of analysis or conformance for each material

• Details on storage and care of your standards

• Certificate of final inspection & recommended re-polishing date

• A replaceable silica gel capsule for protection whilst in transit

• A credit card sized quick reference guide

A copy of the electronic booklet is also accessible from our cloud storage.

Documentation

Documentation