PELCO® Hydrophilic and Hydrophobic Silicon Nitride Membrane Surfaces

PELCO® Hydrophilic and Hydrophobic Silicon Nitride Membrane Surfaces

15nm, 50nm and 200nm membrane thickness

Silicon Nitride membranes have been modified using Atomic Layer-Deposited (ALD) techniques to change their surface properties. Depending on the process used, both Hydrophilic and Hydrophobic substrates have been created with the following advantages:

- Choice between low and high surface energies

- Smooth and conformal substrates

- Enhanced wetting and biocompatibility (hydrophilic)

- No need for plasma treatment of surface prior to cell growth

- Hydrophobic coating offers novel platform for deposition and growth of nanomaterials

Hydrophobic surfaces improve sample preparation for materials that are dissolved or suspended in organics solvents. Nanoparticles in organic solvents (such as carbon nanotubes) will readily disperse on the Silicon Nitride membrane surface.

Hydrophilic surfaces enhance wetting and dispersion of aqueous solutions. This avoids particle aggregation effects commonly observed on less hydrophilic surfaces. Particularly useful in water based sols and life science applications.

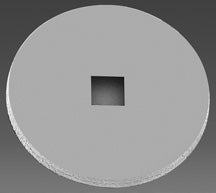

Both coatings are available on 50nm and 200nm PELCO® Silicon Nitride Membranes with a 0.5 x 0.5mm window and 15nm Silicon Nitride membrane with 9 each 0.1 x 0.1mm windows on a 200µm silicon frame with a diameter of 3mm, compatible with all standard TEM grid holders. Both sides of the membrane and frame are coated. We advise to handle the discs by gripping at the edge.

Specifications:

- Hydrophilic: 2.5nm atomic layer-deposited hydroxylated alumina on 15, 50 and 200nm ultra-low-stress silicon nitride membrane

- Hydrophobic: 2.5nm atomic layer-deposited alumina and fluoro-methyl-silane on 15, 50 and 200nm ultra-low-stress silicon nitride membrane

- Surface Energy:

| Surface | Surface Energy (mJ/m2) | Standard Deviation |

| Silicon Nitride Membrane | 46.1 | 4.3 |

| Hydrophilic Coating | 76.1 | 2.2 |

| Hydrophobic Coating | 24.6 | 4.4 |

| mj= millijoules | ||

- Surface Roughness:

| Surface | Surface Roughness (nm) | Standard Deviation |

| Silicon Nitride Membrane | Rq=0.65 Ra=0.45 |

0.06 0.02 |

| Hydrophilic Coating | Rq=0.57 Ra=0.40 |

0.04 0.03 |

| Hydrophobic Coating | Rq=0.66 Ra=0.40 |

0.03 0.05 |

| Rq= Surface Roughness; Ra= Roughness Average | ||

- Film Thickness: Resilient, low stress 15, 50 and 200nm, giving rise to minimum absorption to enable clear imaging

- Window Sizes: Array of 9 ea. 0.1 x 0.1mm and 0.5 x 0.5mm

- Frame Thickness: Silicon support structure is 200µm standard.

- Frame Diameter: EM standard 3mm diameter disc, fully compatible with standard TEM holders (no broken edges)

- EasyGrip™ Edges for easy handling with tweezers

- Packaging: The PELCO® Silicon Nitride Support Films are packaged under cleanroom conditions. Each box holds 10 support films

Documentation

Documentation