PELCO® easiCore™

PELCO® easiCore™

Precision Rotary Disc Cutter & Drill

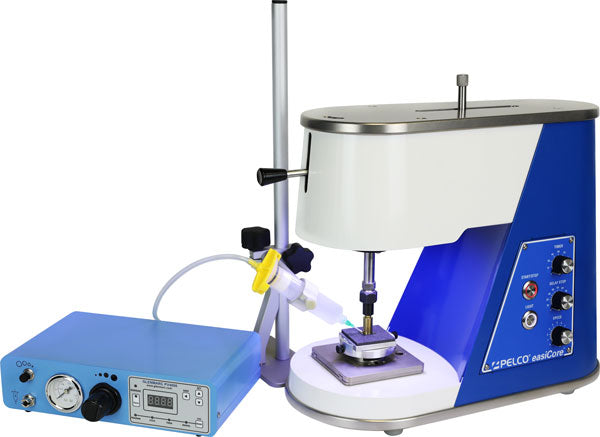

The PELCO® easiCore™ Rotary Disc Cutter is a precision instrument designed to align and cut discs from or drill holes into a wide range of materials using brass core drills and abrasive slurry. The rotating tool is lowered onto the specimen with the force controlled by an easily adjustable counterbalanced weight. The most common application for the instrument is to cut 3.0mm discs for TEM, but a range of metric and Imperial core drill diameters are available for other applications, from semiconductors to battery materials.

Unlike ultrasonic disc cutters that can only cut brittle materials, the gentle lapping action of the PELCO® easiCore™ can cut soft metals, hard ceramics and even fragile crystals. Specimens may be mounted on fixtures that are compatible with the PELCO® Precision Wire Saw™, PELCO® Precision Low Speed Saw™, or PELCO® Dimpler™ for simplification of workflow. Once on the stage, the sample may be precisely positioned in both the X and Y directions by using the sliding X-Y stage with rulers marked at 1mm intervals.

1" Work Table (#76015),

1 x 3" Al Sample Mount (#75053)

on PELCO® easiCore™ Stage

2" Work Table (#76012),

2 x 2" Al Sample Mount (#85051)

on PELCO® easiCore™ Stage

Large Area Platen Set (#83042)

on PELCO® easiCore™ Stage

There are several cutting modes including an automatic stop with an optional timed delay to ensure that samples are fully cut even if they were mounted or cut slightly asymmetrically. There is also a timed mode up to 120 minutes. The variable speed is adjustable from 100–1500 RPM and the load on the specimen is continuously variable up to 1kg (2.2 lbs). For long cuts where abrasive replenishment is needed, the PELCO® easiCore™ is compatible with the PELCO® Abrasive Dispenser for timed/measured dispense of abrasive suspensions.

PELCO® Abrasive Dispenser

set up for the PELCO® easiCore™

Features

- Gentle lapping action cuts virtually all materials including those which cannot be cut with an ultrasonic cutter.

- High tolerance rotational accuracy prevents cracking and chipping of even extremely delicate materials.

- Portability of PELCO® Dimpler™, PELCO® Precision Wire Saw™, and PELCO® Precision Low Speed Saw™ specimen mounts increases throughput and maximizes specimen yield.

- Capable of cutting discs from 2.3–25mm in metric sizes and 1/8–1/2" in Imperial sizes.

- Constant gravity feed mechanism and automatic termination minimize operator supervision.

- Auto-stop switch incorporates a time delay which eliminates the possibility of premature shut-off.

- LED ring light illuminates the stage and allows for easy alignment of the region of interest to the core drill.

- Measured X-Y stage allows for precision positioning during repeated sampling.

PELCO® easiCore™ Specifications

| Power | 100–240 VAC 50, 60Hz |

| Bit Size | metric 2.3–25mm, Imperial 1/8–1/2" |

| Maximum Applied Load | 1kg (2.2lbs) |

| Speed Control | 100–1500 RPM |

| Delay Stop | 30–90 seconds |

| Timer Mode | up to 120 minute run time |

| Overall Dimensions | 17" W x 8" D x 14-1/2" H (381 x 203 x 368mm) |

| Weight | 9.1kg (20 lbs) |

| X-Y Stage | 50mm total travel in X and Y directions |

Accessories for the PELCO® easiCore™

1" Work Table

(#76015)

2" Work Table

(#76012)

Standard

Platen Set

(#83027)

Adjustable

Platen Set

(#83032)

Large Area Platen

with Base

(#83042)

Platen Sets for the PELCO® Dimpler™ are compatible with the stage of the PELCO® easiCore™. Choose from the Standard Platen Set, Adjustable Platen Set or the Large Area Platen Set.

The PELCO® easiCore™ is shipped with everything needed to operate, including: the 1" Work Table (#76015), Aluminum and Graphite Sample Mounts, 3mm and a 1/2" Core Drill Bits, as well as Mounting Wax and Abrasive Powder.

All accessories can also be ordered individually.

Consumables for use with the PELCO® easiCore™:

Grinding Powders

Polishing Compounds, Paste, Sprays, Suspensions

Mounting & Fixturing Adhesives & Waxes

Brass Core Drills for PELCO® easiCore™

Solid brass, thin wall brass core drills with internal diameters of 2.3–25mm in metric sizes and 1/8–1/2" in Imperial sizes.

Documentation

Documentation